1-203-200-0302

sales@apextoolworks.com

Mon-Sat 9AM - 6PM EST

Continuous vs. Pulse Laser Cleaners: Which One is Right for You?

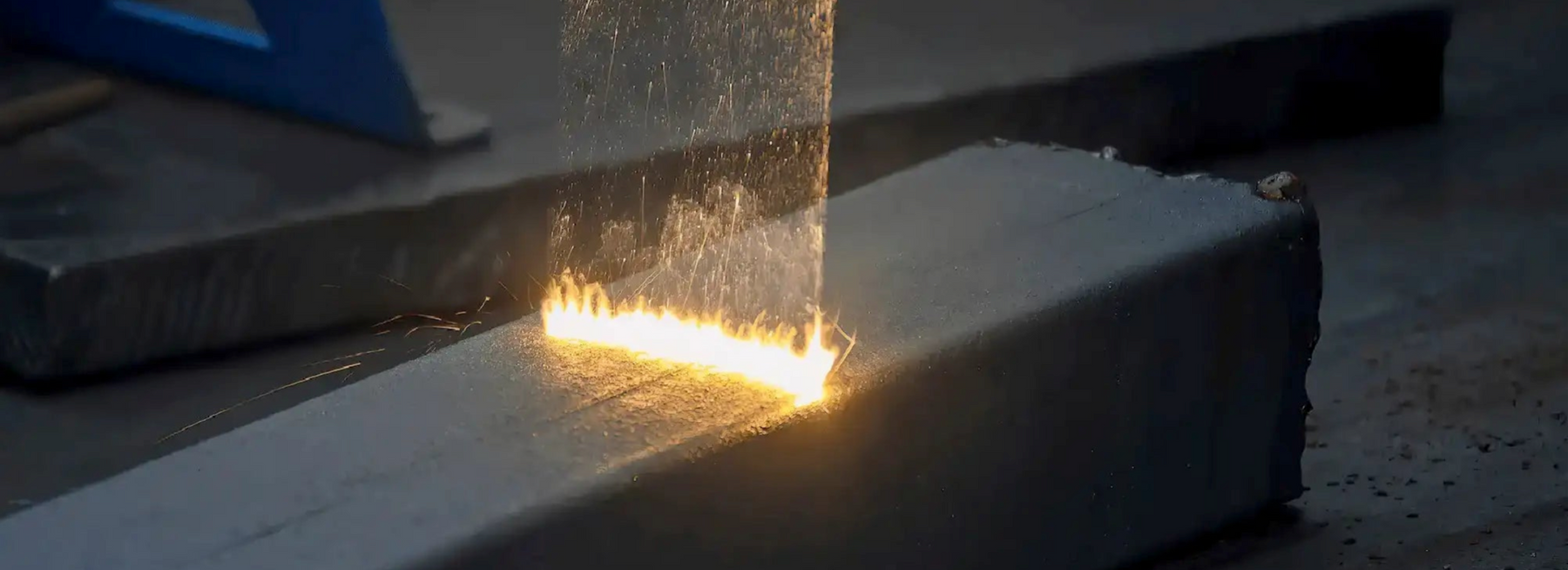

There are two main types of laser cleaners: Continuous Wave (CW) Laser Cleaners and Pulse Laser Cleaners. Both are effective tools for removing rust or paint from material surfaces, achieving thorough cleaning results.

However, they differ significantly in efficiency, control over heat input, and suitability for various applications. The following table summarizes the differences and intended applications of both types of cleaners.

| Feature | Continuous Laser Cleaners | Pulse Laser Cleaners |

|---|---|---|

| Advantages |

|

|

| Limitations |

|

|

| Applications / Use Cases |

|

|

Ultimately, there is no single "one-size fits all" cleaner, and both types should be part of the arsenal of any cleaning operation.

What Power Level Do I Need when Deciding on a Laser Cleaner?

The power level depends on how quickly and efficiently you need to clean the surface, what the application is, and also what the overall budget is (short term and long term).

For example, for large scale industrial cleaning of rust, you might want a 3000W CW laser cleaner, and for smaller scale cleaning of metal tools or parts, a 1500W laser would suffice. It is still possible to use a pulsed machine to clean rust off parts for smaller scale projects (e.g. cleaning engines, tools), but the efficiency will certainly be lower than if a CW machine was used. This is also why pulsed machines are air cooled, while CW machines require liquid cooling.

As another example, if one compared a 200W vs 500W pulsed laser cleaner, the actual cleaning efficiency is approximately 4x higher for the 500W machine. This comes at an extra cost, but pays off in terms of significantly faster cleaning.