GMC Pittsburgh Lockformer Machine PL-16E

The Lockformer Pittsburgh Machine PL-16E from GMC Machine Tools is a versatile and reliable machine for sheet metal fabrication.

- 5 forming stations

- Capacity: 16 Ga to 20 Ga

- Depth of Pocket: ½”

- Feeding Speed: 23 FPM

- Main Motor: 3 HP, 220V 3-PH

The Lockformer Pittsburgh Machine PL-16E from GMC Machine Tools is a versatile and reliable machine for sheet metal fabrication.

- 5 forming stations

- Capacity: 16 Ga to 20 Ga

- Depth of Pocket: ½”

- Feeding Speed: 23 FPM

- Main Motor: 3 HP, 220V 3-PH

Description

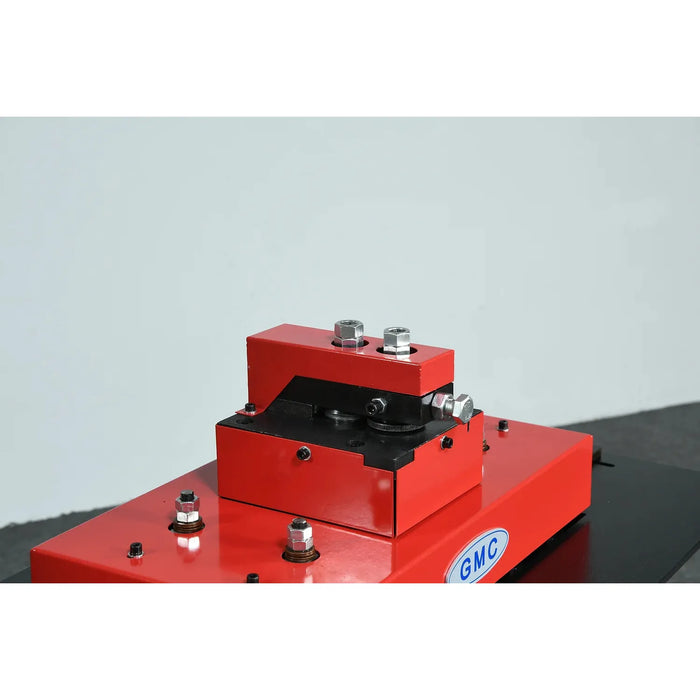

The Lockformer Pittsburgh Machine PL-16E is made with high-quality components and features a heavy-duty frame for durability. The machine is also equipped with a powerful motor to provide consistent and reliable performance.

Other features of the Lockformer Pittsburgh Machine PL-16E include:

- 16 gauge capacity

- 5 forming stations

- Creates Pittsburgh seams, standing seams, and various other ductwork shapes

- Heavy-duty frame for durability

- Powerful motor for consistent and reliable performance

If you're looking for a machine that can handle a variety of ductwork shapes and produce high-quality results every time, the Lockformer Pittsburgh Machine PL-16E is the perfect choice. Order yours today and take your sheet metal work to the next level.

Features

- 16 gauge capacity: The PL-16E can handle sheet metal up to 16 gauge, making it suitable for a wide range of applications.

- Creates tight, interlocking joints between two pieces of sheet metal

- Made with high-quality materials and construction for durability and longevity

- Maintenance-friendly design: The machine is designed for easy maintenance, with quick-access panels that allow for easy cleaning and lubrication.

- Compact and portable design for easy storage and transport

- Compatible with a variety of Lockformer accessories and attachments for added versatility and functionality

- ISO 9001 certified

- 3 HP Heavy Duty AC main motor, 220V, 3 phase

- Standard Pittsburgh Attachment

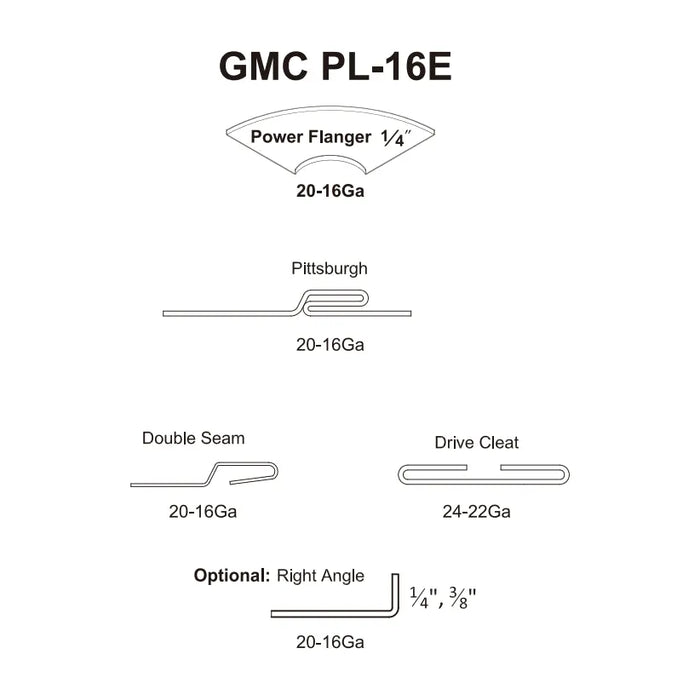

- Standard Round Power Flange Attachment, Double Seam Roll and Drive Cleat Roll (power flange attachment can only do radius parts)

- ACME side can be operated at same time

- Heavy duty caster wheels for easy moving

Standard Equipment

- Standard Pittsburgh Attachment # PA-16E, installed

- Power Flange Attachment # FA-16E, installed

- Drive Cleat Roll # DCR-16E, installed

- Double Seam Roll # DSR-16E, installed

Specifications

|

Capacity: Pittsburgh Lock |

20 Ga. - 16 Ga. |

| Double Seam Lock | 20 Ga. - 16Ga. |

| Drive Cleat Lock | 24 Ga. - 22 Ga. |

| Power Flange 1/4" | 20 Ga. - 16 Ga. |

| Depth of pocket | 1/2" |

| Feeding speed | 23 FPM |

| Main Motor |

3 HP, 3 Phase 10 AMP Prewired: 220VAC 220V, 1 phase is optional |

| Weight | 628 LBS |

|

Machine Dimensions (LxWxH): Shipping Dimensions: |

43" x 27" x 48" |

FAQs

1. What is a Pittsburgh Machine?

A Pittsburgh Machine is a tool used for creating tight, interlocking joints between two pieces of sheet metal.

2. What are the advantages of using a Pittsburgh Machine?

Pittsburgh Machines are more cost-effective, time-saving, precise, and versatile than other methods of sheet metal fabrication.

3. What are the different types of Pittsburgh Machines?

The different types of Pittsburgh Machines include manual, electric, and hydraulic machines.

4. How do I choose the right Pittsburgh Machine for my needs?

Consider factors such as the frequency of use, the size of your shop, and the types of sheet metal products you need to fabricate.